Solar photovoltaic connectors use specially designed contacts and insulation materials to ensure the stability and safety of electrical connections. And can withstand the harsh conditions of outdoor environment, including high temperature, low temperature, ultraviolet radiation, etc. They usually use materials with good weather resistance, such as special plastics or metal alloys, to ensure long-term reliability and performance stability. However, corrosion may also occur in solar connectors during use.

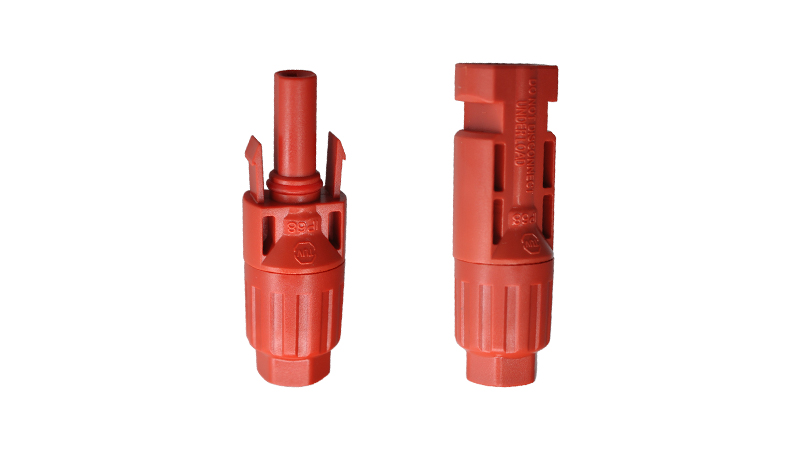

Shunkonn 1000V solar photovoltaic connector

The main reasons why solar photovoltaic connectors may corrode include the following:

【Humidity and moisture】

Solar photovoltaic connectors are usually installed in outdoor environments and are susceptible to humidity and moisture. Prolonged exposure to wet or rainy conditions can cause moisture to penetrate into the connector and cause corrosion. Especially in seaside areas, the corrosive effect of salt on connectors is more obvious.

【Chemical substances】

Certain chemicals, such as acidic or alkaline compounds, industrial pollutants, or agricultural chemicals, may come into contact with the connector surface and cause corrosion reactions. These chemicals may come from the surrounding environment or be released from other equipment, resulting in connector damage.

【Temperature variation】

Photovoltaic systems experience temperature changes during use, from extreme high temperatures to extreme low temperatures. This temperature change can cause expansion and contraction of the connector material, which can lead to tiny cracks and breakage between connector components, providing an opportunity for corrosion.

【Electrochemical reaction】

In photovoltaic systems, electrochemical reactions between different metal materials may lead to corrosion. When different metals are in direct contact and an electrolyte, such as water in humidity, is present, the battery effect occurs, which leads to metal corrosion.

In order to reduce the corrosion problem of solar connectors, the following measures can be taken:

【Use weather-resistant materials】

Choose materials with good weather resistance and corrosion resistance to manufacture connectors, such as stainless steel, weather resistant plastics, etc.

【Sealed protection】

Make sure the connector has good sealing properties to prevent moisture and humidity from entering the inside of the connector. Sealant or seal ring can be used to provide additional protection.

【Surface coating】

Surface coating of connectors, such as electroplating or spraying with special anti-corrosion layers, is applied to enhance their corrosion resistance.

【Maintenance routine】

Inspect and clean connectors regularly to ensure that their surfaces are clean, and repair or replace damaged connector parts in a timely manner.

Shunkonn 1500V solar photovoltaic connector

If you have more questions or need more information, please contact us and our professional team will be happy to support and answer you.

You can also contact us directly in the following ways: visit, telephone, email